Tuesday, February 15, 2022

Time: 3h

- Reserved 67BH for the build

- Spoke with Bob Barrows about weight and balance using light weight O-200, carbon fiber prop, minimal instruments, carbon fiber nose bowl, light weight battery, etc... He said things will be fine that his C-85 is about 30 pounds lighter than my O-200 and no issues there.

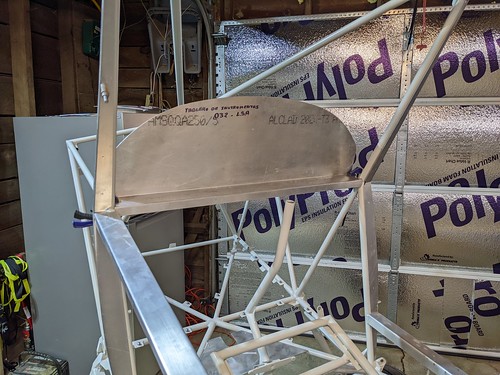

- Slightly trimmed instrument panel so it would fit, not working on the panel right now just wanted to see it sitting there :-)

- Drilled and tapped rear most seat stops.

- Mounted the door simply to get an idea how well it swings, what the clearance is, etc.

- Mounted the front most floor, wrapped a few straps around the front seat and tossed on some thin cushions to get an idea of where I may have the seat set for myself. All the way back is probably too far, but one from the rear most setting will probably be just right for me.

Seat Stops

The LSA has bolts welded to the seat frame on the rear slides. The plans then show four holes drilled into the rails tha the seat slides on. I am not overly excited about this method of an adjustable seat. It is simple and light weight but is it functional enough for me.

I was unsure if the holes drilled should be tapped or not. I tapped them. Not tapping them would be easier, but if they are not tapped then I am afraid that the bolt threads that protrude into the lower seat rail will be damaged in time and thus not back out of the bolt welded to the seat itself.

Photo Stream

Bolts welded to the rear seat slides

Instrument Panel in place to get an idea of forward visibility with various seat locations

Clamping the seat into position while I mark where to drill the holes for seat stop

Rear most seat stop holes drilled, tapped, and bolts actually thread in!